Standardizing is a verb, just like any other process step

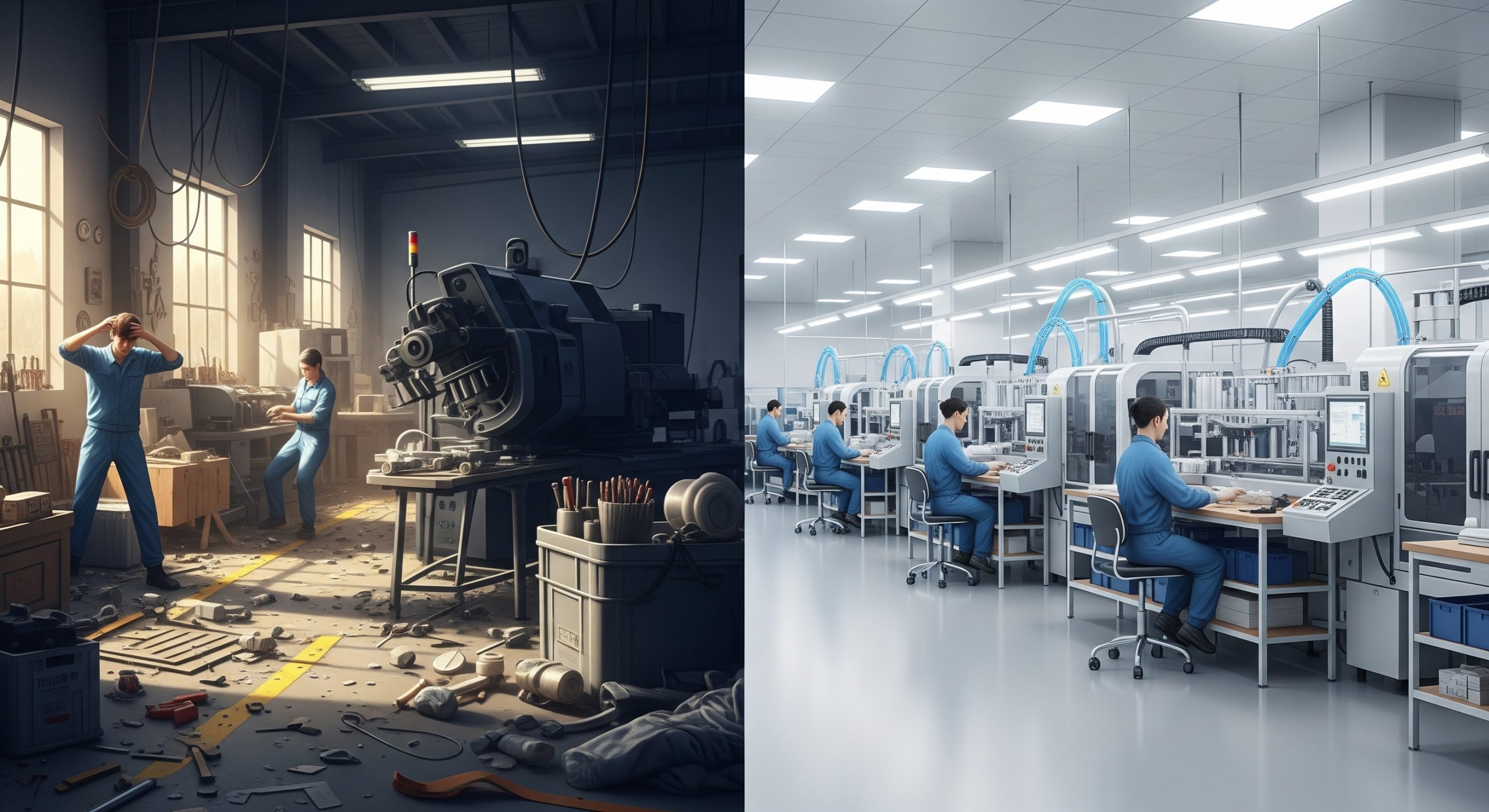

We’ve all been there. You’re juggling a million things, putting out fires left and right, and while the final product might be beautiful, the path to get there feels like navigating a minefield blindfolded. It’s a familiar story in production: a focus on the what – the final output – often overshadows the crucial how – the processes that bring it to life. And that is a recipe for frustration, wasted resources, and ultimately a shaky foundation. There’s a tempting notion that a “natural” approach to production, where things evolve organically, is somehow superior. But think about it: relying solely on individual expertise and ad-hoc solutions is a gamble. What happens when key personnel are unavailable? What if a slight shift in materials throws everything off? The truth is, without a solid framework, even the most exceptional ingredients can lead to a flawed final product. A good chance that the cause can be found in the failure to implement process standards properly which is just as important, if not more important than any other process steps.

Why standardize processes?

For your product, specifications have been compiled with care; they form a quality standard for the product. When an unbalanced process tries to comply to these values, there is a good chance it will produce a sub-optimal outcome. The quality of the processes has to be in harmony with the product specification; only then it will be possible to meet the customer’s expectations.

Think about Albert Einstein’s famous definition of insanity: doing the same thing over and over again, but expecting a different result. In production, we often see the opposite, but with the same result: trying to make the same product with different settings every day.

When you always act and react on the product in the same way, you can expect the same result. Standardizing the production process creates predictability, and as boring as that sounds, that is what is strive for in production. When the process is predictable, so is the quality of the product.

Next to that, when the process is not standardized, you can only improve at random. After all, without a standard, everything appears to be okay!

Why is standardizing processes is so difficult?

First of all, it is difficult for people to deal with standards. It only gets easier when you don’t have to think about it anymore. When it becomes a (new) normal.

Driving on one side of the road is a good example; no one thinks about it, but imagine what chaos it would be if we all tried to find our own place on the road. The difficulty? Try taking a roundabout in a place where it is normal to drive on the other side of the road! Let’s assume the right side of the road is normal, and until you get used to the new rule, you experience mental resistance and sometimes even panic. (Those red double-deckers do have very large bumpers…)

It sounds so simple, you just write down what needs to be set, and then it will all be fine. If it were really that simple, there would be nothing wrong. Yet, compiling standards is not simple at all. In the beginning, everyone is full of good will, but when it is not clear what needs to be done when and by whom, the lists of settings turn into a kind of wallpaper that no one really sees anymore. When the deviation in the process leads to major problems, the standards are not the place to look, but the best firefighter is richly rewarded for the ‘good’ work on temporarily get the process to behave in the right way. Another phenomenon is that after setting a standard, no one looks at the default anymore because the settings have no tolerance. (If a setting does not change, why push that button still then?)

Processes are also subject to change. We have to deal with wear and tear, weather influences and probably the supplier of raw materials does not have as good control over its processes as you would like. When the default settings do not move along with this, it is less and less likely that they will produce the right end product. On the other hand, you also don’t want to upset the balance of the process every week by redefining all the settings. Also here it is very important to find the balance between process knowledge and control.

How Can it Be Done? Laying the foundation for success.

While the path to standardization might have a few bumps, the rewards are well worth the effort. A clear process standard is composed with and by operators and has as few settings as possible with clear and proven tolerances so that it becomes clear what can be set.

- A clear process standard is composed with and by operators and has as few settings as possible with clear and proven tolerances so that it becomes clear what can be set.

- In addition, a management plan makes it clear how and when to intervene in the event of deviations from the product that produces the process step. All this can be found and reproduced at a glance, preferably digitally.

- There is someone as close to the process as possible who is responsible for the measured effectiveness of the standard and its maintenance. Compliance to quality is measured according to Statistic Process Control or AI tools.

- When the correct product quality is not generated within the default settings, the root cause is resolved or tests are performed that prove the new default settings or tolerances (in that order)

- Employees learn to work with the standard by properly mapping out its results, regularly updating the standard itself.

- Management discusses resistance to work with the standards, instead of celebrating it.

By embracing standardized processes, you’re not stifling creativity; you’re building a reliable framework that allows innovation to flourish on a stable base. You’re moving from reactive firefighting to proactive control, empowering your team and ensuring consistent, high-quality results. So, take the plunge. Define your processes, empower your people, and watch your production thrive.

It’s not the tools, but how you use them.

Have fun controlling production processes!